Accessories

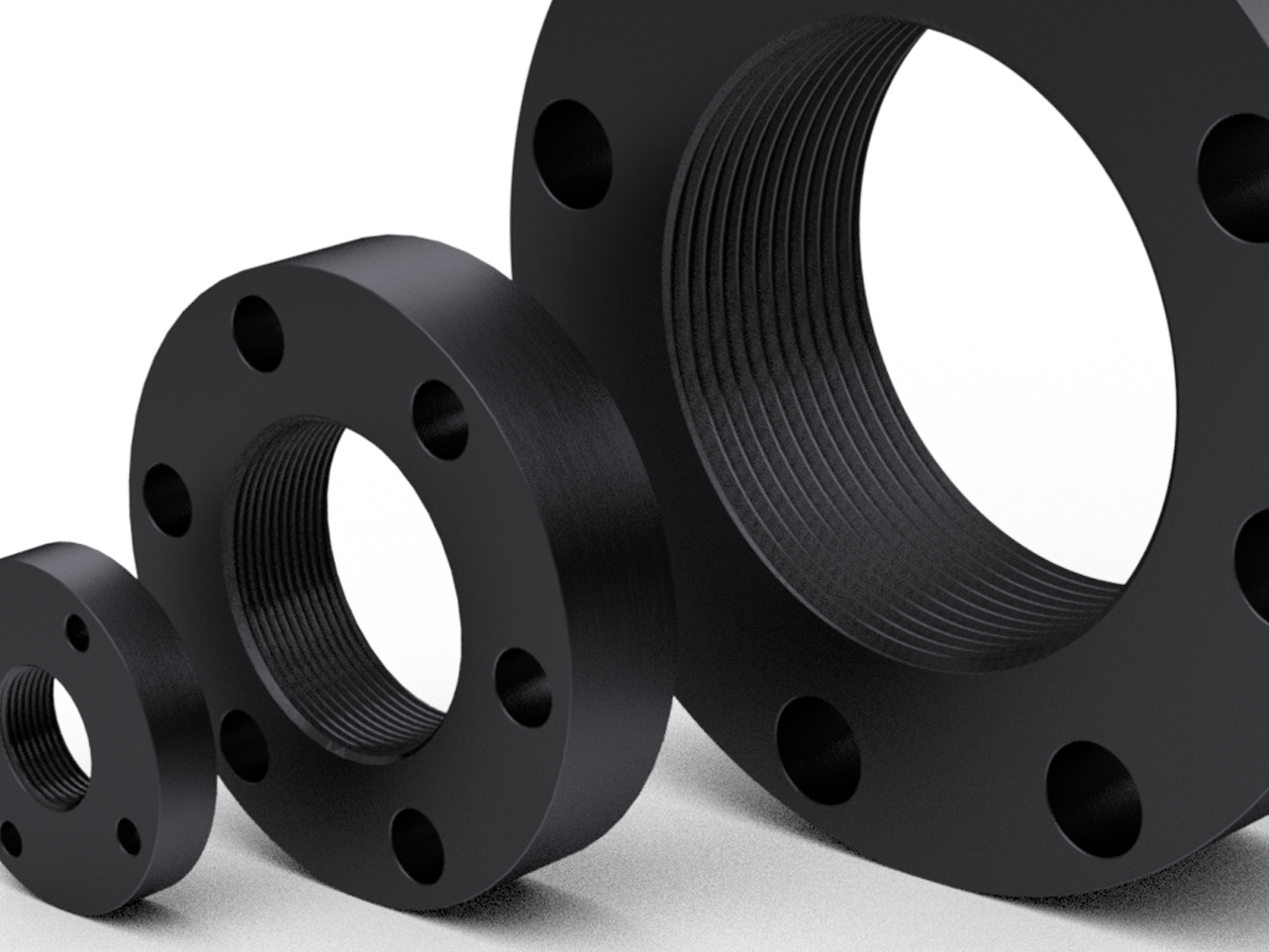

Mounting Flanges

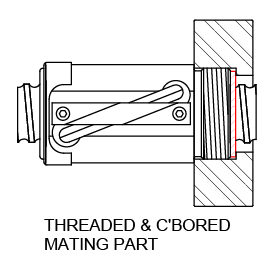

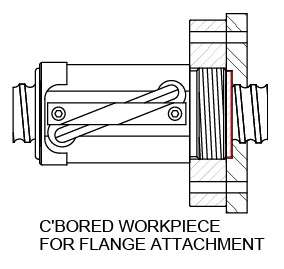

Flanges are available for all standard models and custom flanges can be made to specifications. When using a mounting flange instead of the standard v-thread on the ball nut body, it must be permanently attached to prevent disengagement during operation.

Advantages:

- Custom mounting condition

- Lubrication porting

- Custom bolt hole location and size

- Customer-specific material options

Mounting Flanges

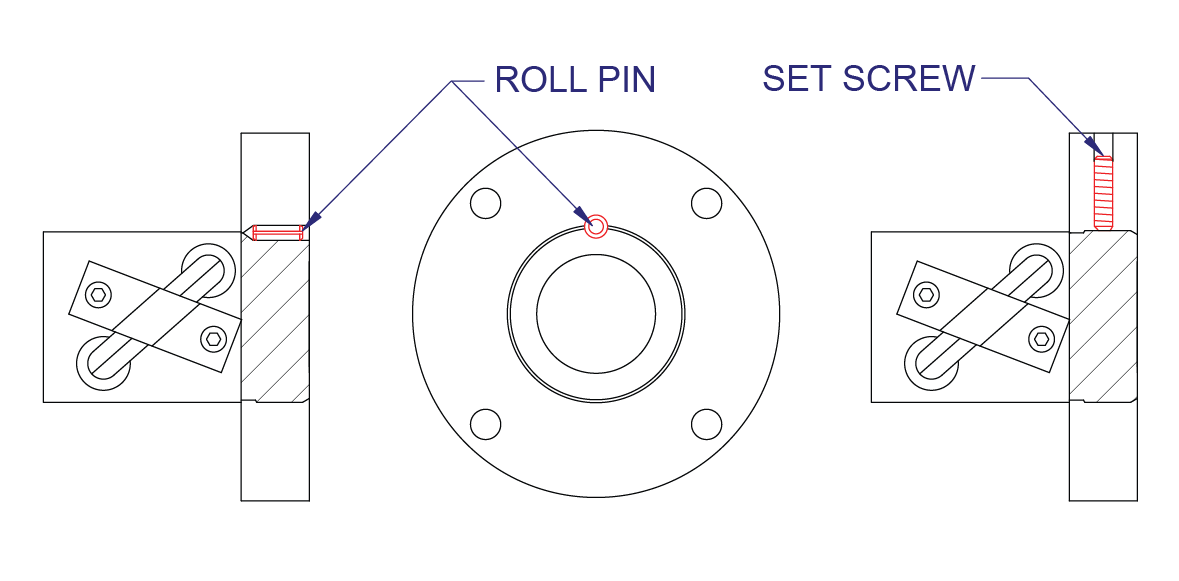

If a mounting flange is used instead of the standard v-thread on the ball nut body, it must be permanently attached to prevent disengagement during operation. The two standard methods of retaining the flange is pinning and retaining with a set screw. Commercial thread locking adhesives may also be used (light loads only). It is always recommended that the flange pinning be performed at the factory to assure no metal chips are present after drilling.

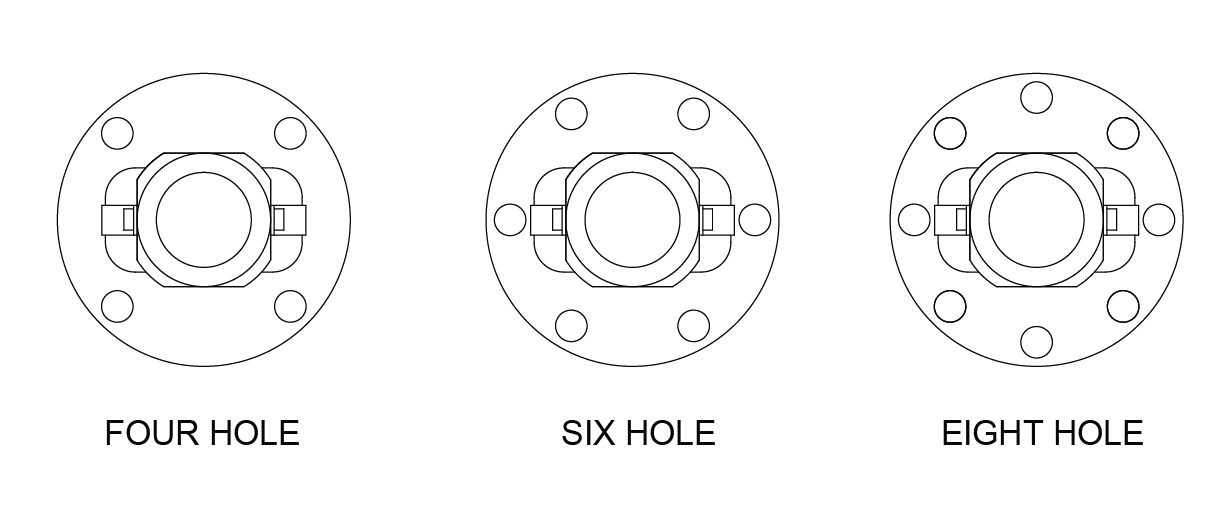

Flange Orientation

The orientation of the flange bolt holes to the return tube components varies with the number of holes in the flange. Unless otherwise specified, the following illustrations represent the standard orientations.

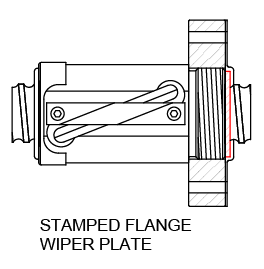

Wiper Kits

Polymer brush wipers are designed to keep large particulates from entering the ball nut. Wiper kits are available for all standard ball screw models. For harsh environments, the use of boots or bellows to enclose the screw is recommended. Contact Rockford Ball Screw for further information on enclosures.

Wiper Kits

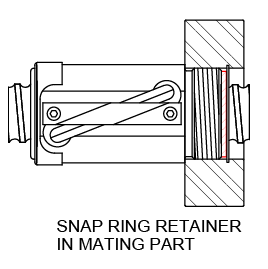

Our product catalog pages detail the type of wiper mounting arrangement for each ball nut model. Brush wipers may require customer supplied retention primarily on the V-thread end of the ball nut (on models that do not have internal wipers and snap rings). A stamped flange retainer is available for many models that do not have internal snap rings for wiper retention (see data pages for available sizes).

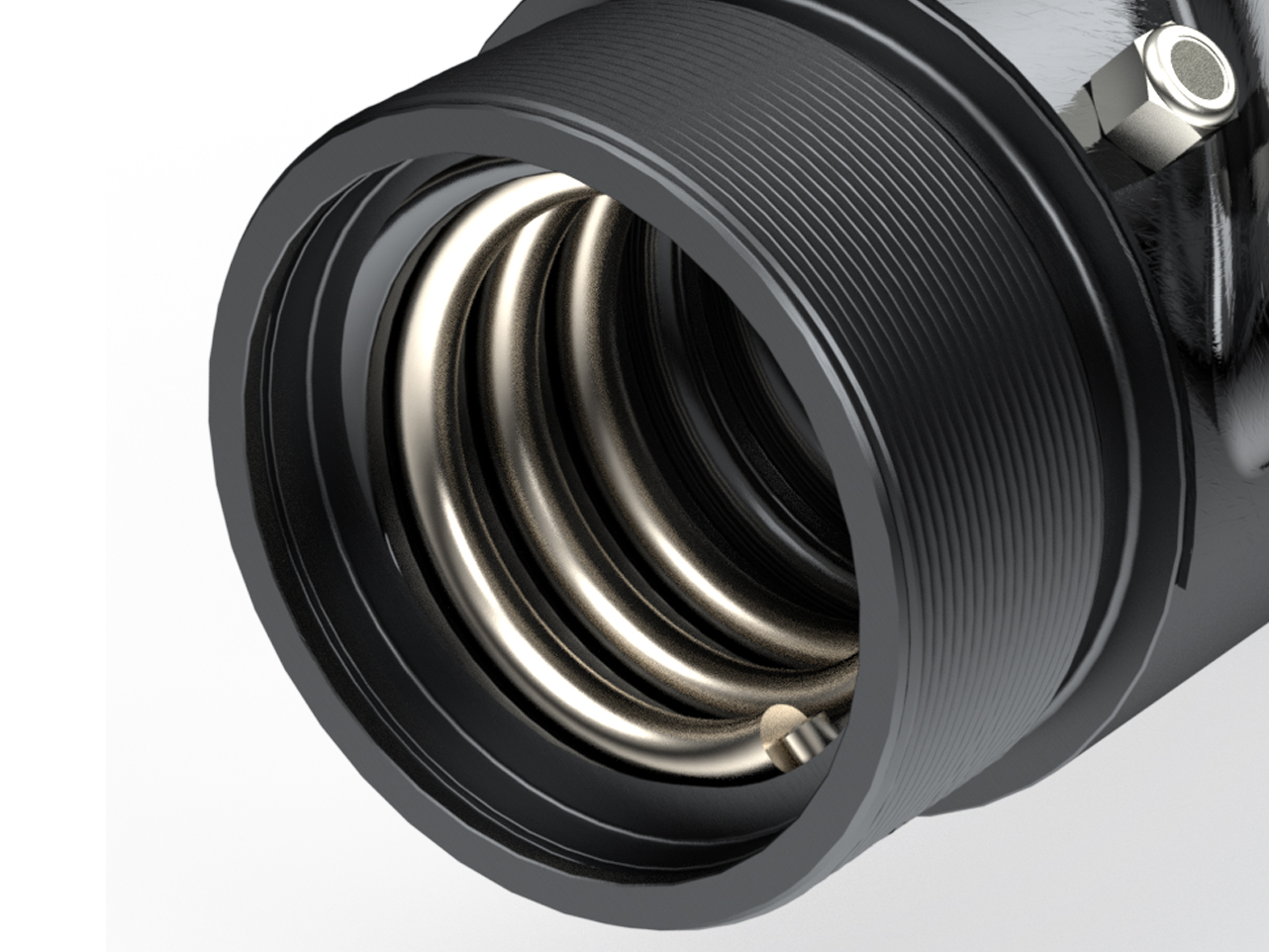

Safety Springs

The safety spring is a coiled spring in the inactive part of the ball nut that conforms to the ball screw thread. The spring is inactive during normal operation and does not contact the screw. In the rare event that the balls are lost from the ball nut, the safety spring will support the load and prevent the nut from “free falling” down the screw. Safety springs are mandatory if the ball nut is used to lift, and/or support people to prevent the ball nut from a free fall condition in case of a ball nut catastrophic failure.

The spring is not designed to maintain normal operation and the ball screw assembly should be taken out of service after first engagement of spring. Safety springs are available for all ball screw models. Please inform our customer representative that you require the safety spring for your application.

Lubrication

Rockford Ball Screw provides recommended lube for ball screw and ACME screw products. Lubrication is required to achieve optimum life for a ball screw assembly. Ball screws that are not lubricated can experience up to a 90% reduction in calculated life. In general, standard lubrication practices for anti-friction rolling element bearings apply. Many ball nuts are equipped with a 1/8-27NPT lube port machined into the nut body. For models that do not have a factory lube port, contact Rockford Ball Screw factory for recommendations regarding application of lubrication.

RBS’ multi-purpose grease has been specifically formulated with extreme pressure and anti-wear additives to reduce rolling element friction, wear, and provide noise dampening characteristics. RBS recommends this grease for ball screws, bearing mounts, CME mounts and other applications requiring excellent hydrodynamic lubrication.

Lubrication

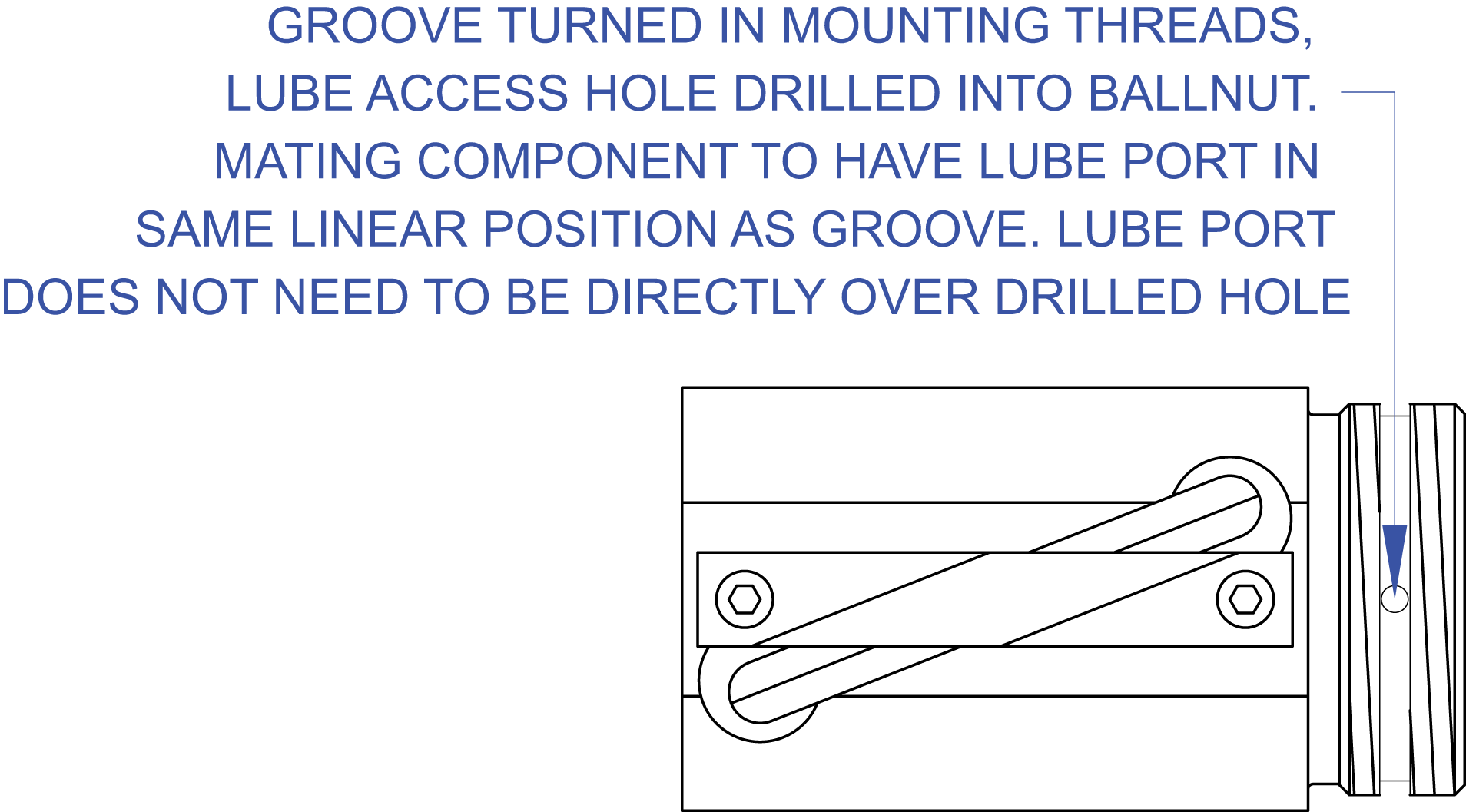

Lubrication of the ball screw assembly is extremely important to maintaining optimum efficiency and life. The ideal access point of introducing the lubrication is directly into the ballnut. Below we have illustrated a number of methods that have been utilized to ease the process of lubricating the ballnut. Should none of the methods apply to your application, please consult factory.

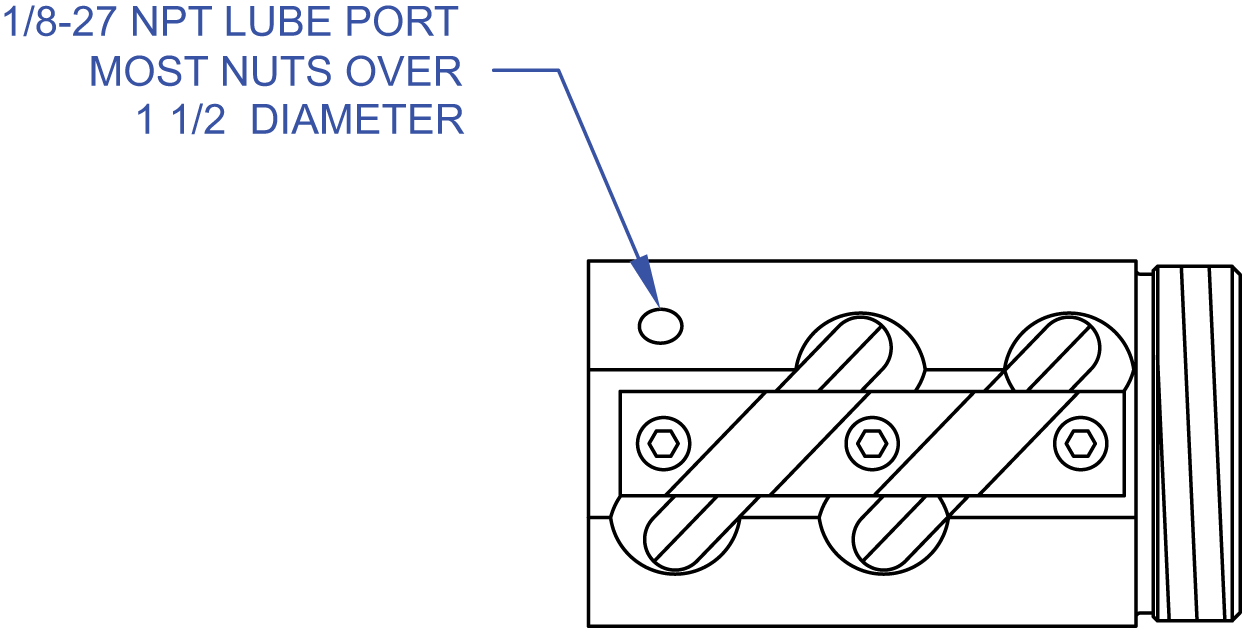

LUBE PORT INCLUDED ON BALLNUT

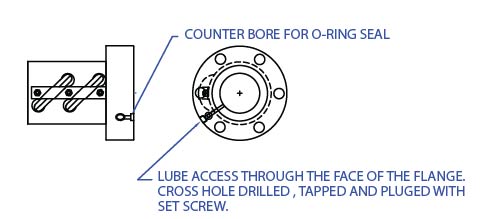

LUBE PORT IN FACE OF FLANGE

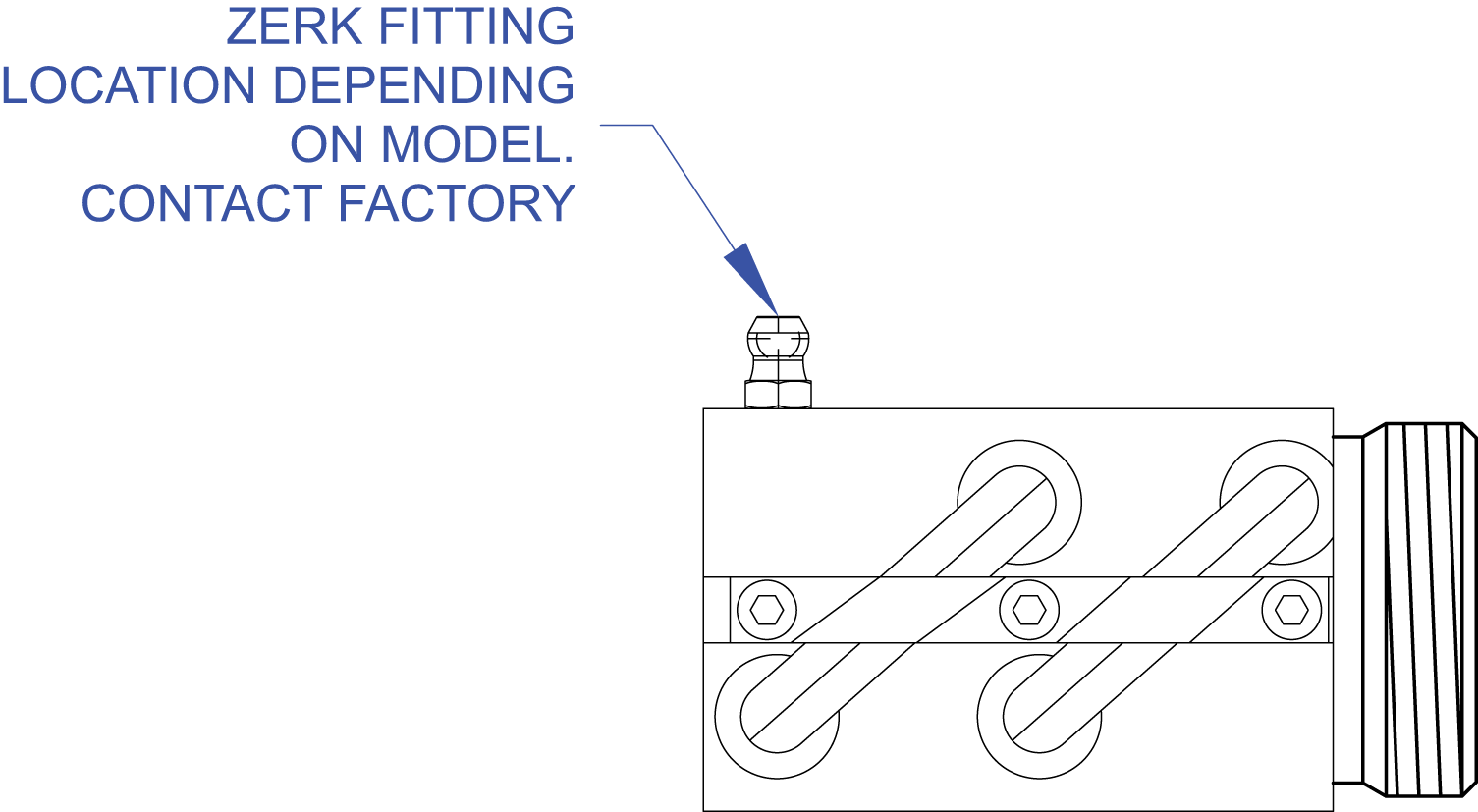

ZERK FITTING INSTALLED IN SIDE OF NUT

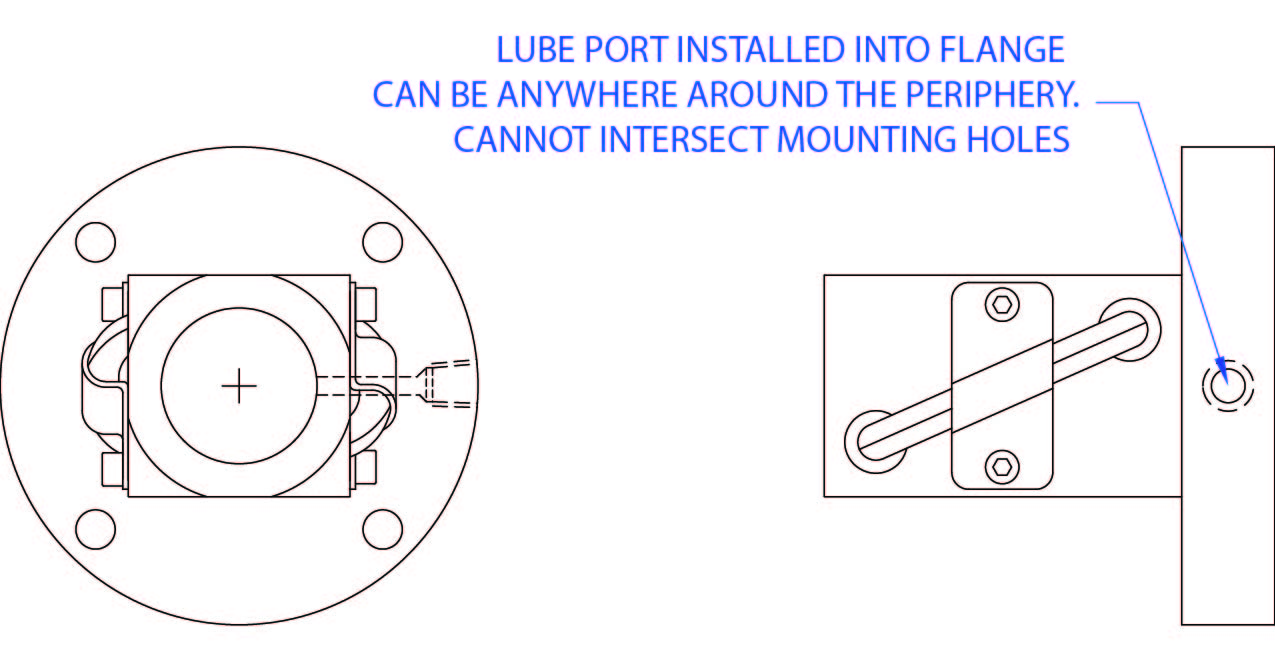

LUBE PORT INSTALLED IN FLANGE

LUBE ACCESS HOLE IN GROOVE OF MOUNTING THREAD

RBS Multi-purpose Synthetic Grease

AVAILABLE IN 14 OZ. CARTRIDGES

NOTE: To achieve optimal grease performance, it is recommended that the machine components should be kept in careful alignment, the operating environment should be kept clean, and the assembly should be periodically inspected for proper lubrication quantity and integrity.

Advantages

Proper lubrication along with reducing/eliminating foreign contamination are essential for preventing premature catastrophic failure. The R/B/S multi-purpose PTFE fortified synthetic grease has been specifically formulated with extreme pressure and anti-wear additives to reduce rolling element friction, wear, and provide noise damping characteristics. The excellent mechanical stability allows for compatibility with ferrous metals, non-ferrous metals, and most engineering plastics.

Consult the factory for specific material interactions. R/B/S recommends this grease be used for ballscrew, ACME screws, bearing mount, and other applications requiring excellent hydrodynamic lubrication.

Data Multi-Purpose Grease Specifications:

| NLGI Grade: | 2 |

| Temperature Range: | -40ºF(-40ºC) to 275ºF(135ºC) |

| Base Fluid Viscosity (cSt): | 75 @ 40ºC 12 @ 100ºC |

| Worked Penetration: (ASTM D1403) | 291 |