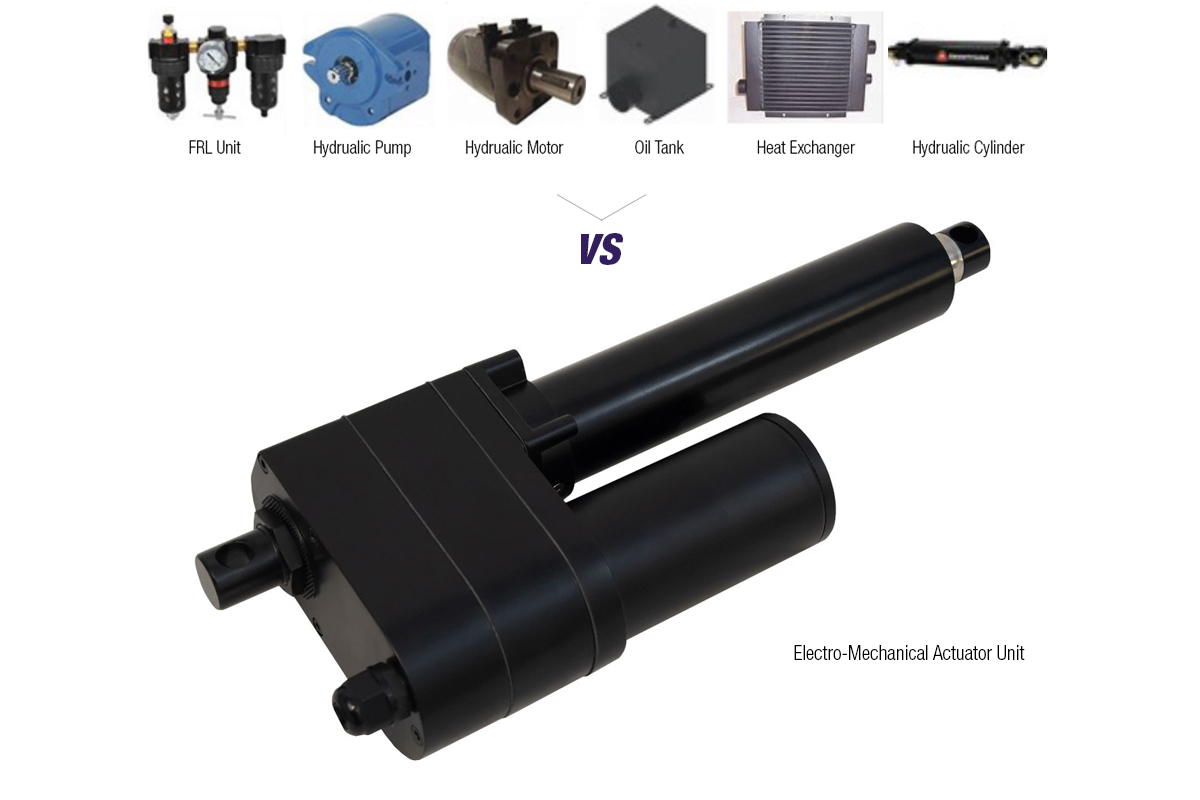

HYDRAULIC VS. ELECTRO-MECHANICAL

Ball Screw driven electro-mechanical linear actuators are increasingly becoming the preferred choice of actuation over the equivalent hydraulic or pneumatic systems. Some of the advantages include simpler installation (fewer components) along with a cleaner, healthier, and quieter environment. After the installation you can look forward to lower energy costs with less maintenance.

Advantages of Electro-Mechanical Solutions are:

- Higher Performance

- Accurate and smooth delivery of force

- Increased range of actuation as the stroke position is easily and quickly varied

- Electro-mechanical solutions are more resistant to temperature variations

- Complete control of the entire motion profile using standard control methods

- Repeatable and accurate positioning

- Reduced Costs

- Environmentally friendly

- Increased Safety

The ball screw electro-mechanical system is generally less expensive and easier to install when compared to a hydraulic system when the required ancillary hydraulic equipment is included.

In contrast, a ball screw driven actuator consists of a single unit.

Electronic actuators are easier to install, reducing the cost of installation and long term maintenance. Ball screw driven electro-mechanical actuators only use power when moving the load. In comparison, hydraulic systems generally have to maintain pressure levels to either maintain position when holding a load or to ensure that the system can respond when required.

Electro-Mechanical driven machinery requires less maintenance with no hydraulic oil to maintain, no leaks to repair and fewer system components to monitor. Hydraulic oil leaks are bad for the environment, create maintenance issues, and can be a safety hazard.

Ball screw driven electro-mechanical actuators remove the risk of contaminating the environment, buildings or product due to the elimination of hazardous hydraulic fluid. Also, there is less manual intervention on machinery to set up processes as electro-mechanical solutions can be controlled over the complete motion profile. Electric systems are quick and simple to program and tune for an application including the accurate synchronization of multiple axes.