KAIZEN-IMEC

Our goal of driving continuous improvement in processes, lead times and quality never ends. Since July, we have taken that commitment to the next level with IMEC Illinois through their lean implementation, or kaizen, training. Kaizen, a Japanese term, translates to the Japanese philosophy of continuous improvement of workplace practices within the facility.

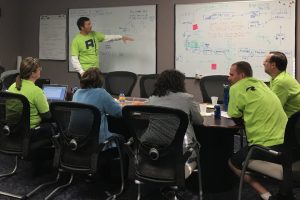

Representatives from IMEC have worked alongside of our Rapid Action Team, our designated lean implementation champions, to identify the objectives and hurdles and have pulled together a timeline of implementation.

Over the past few months, we have implemented the following steps and are already seeing the results:

- In August, we started with the 5S's, a Japanese concept focused on improving sorting, straightening, shining, sustaining and standardizing processes. We spent one session cleaning, organizing and working through footprints of how to eliminate wasteful movements.

- In September, we reduced the production time through process change. By changing the flow of the work cell and quick-change tools, we were able to exceed our goal of 50% and reach a reduction of 60%!

- In October, we were learning the Kanban inventory pull system for our top customer. The goal is to reduce lead times and guarantee on time delivery while simplifying the entire process flow.

The goal of our IMEC sessions is to roll out the concepts of lean implementation to the entire RBS organization through the help of our Rapid Action Team champions.