Manufacturing

RBS is a full service vertically integrated linear motion manufacturer that rapidly takes an idea from concept to production, let our team help solve your linear motion needs.

- Auto feed and multi-pallet CNC machining centers for high volume requirements allowing for lights out autonomous production

- Quick changeover CNC machining centers for low volume requirements

- Specialty machining centers for screw splicing, flange pinning and part deburring

- Auto feed centerless grinding to prepare bars for screw production

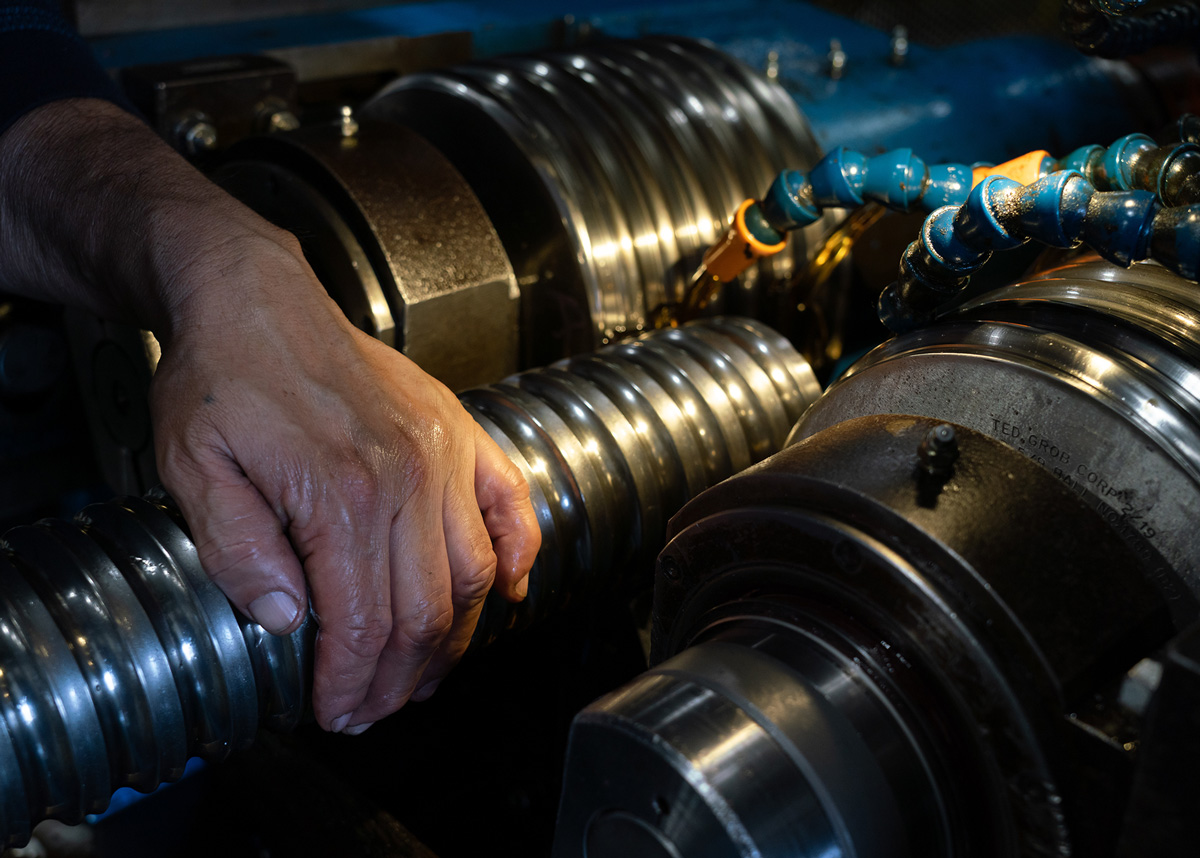

- Roll threading systems to cold work screws for maximum material performance, strength, accuracy to .002”/foot, fine surface finishes and optimum screw value

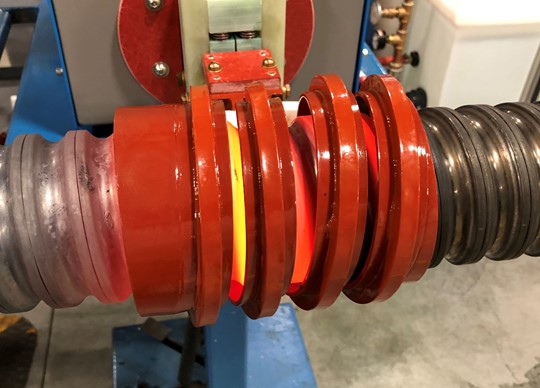

- Induction scanning systems for case hardening ball screws up to 60 Rc, from 3” to 28’ in length

- Annealing systems for targeted softening of material for machining

- Wet abrasive and horizontal band saws with auto-feed systems

- OD grinding for precision finishes and tolerances

- Straightening systems to ensure tight runout control up to .002”/foot

- Parts cleaning, prepping, black oxide treating and rust preventive oil coating systems to prevent corrosion during storage and transit

- Assembly cells with specialized equipment and fixtures to inject ball bearings, torque fasteners, inject grease, press-mount sleeves, press-mount bearings on screws and other components to provide value-added ready-to-use linear motion assemblies for rapid insertion into your products

- Packaging cells and wood shop for building 100% recyclable cartons and crates for safe product shipment, storage and use on your production lines

- Returnable packaging programs available to minimize costs and your carbon footprint