Rockford Ball Screw (RBS) is a recognized industry leader in the design and supply of custom ball screw products, particularly for the energy sector, and is the preferred choice for many in the oil and gas industries.

We specialize in developing custom solutions that meet the specific needs of our clients, especially in high-pressure applications such as frac gate valves (frac valves) and well completion actuators using steel alloys, stainless steels and super alloys, such as Inconel and MP35N.

Key Features and Applications

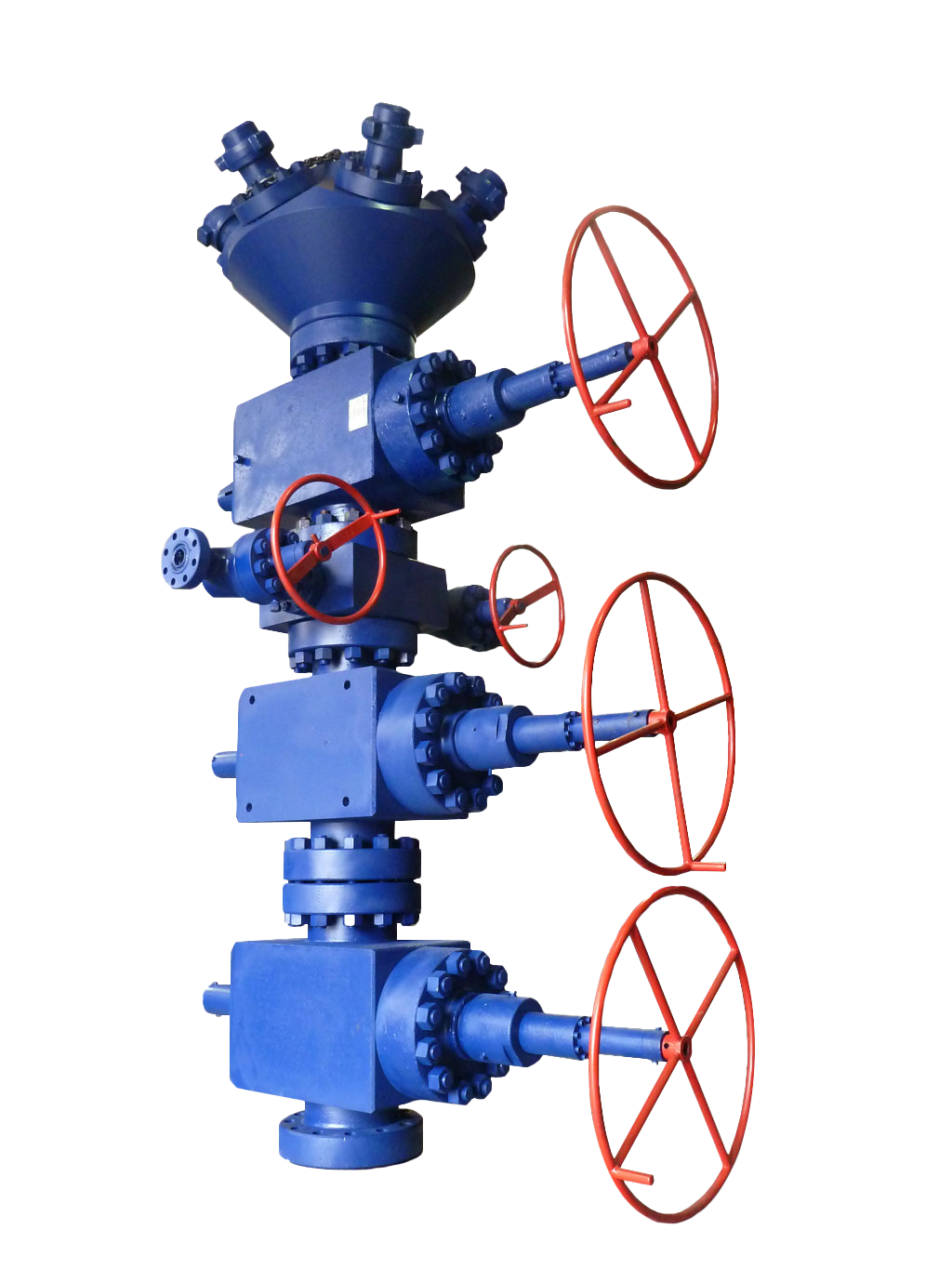

Gate Valves (Frac Valves)

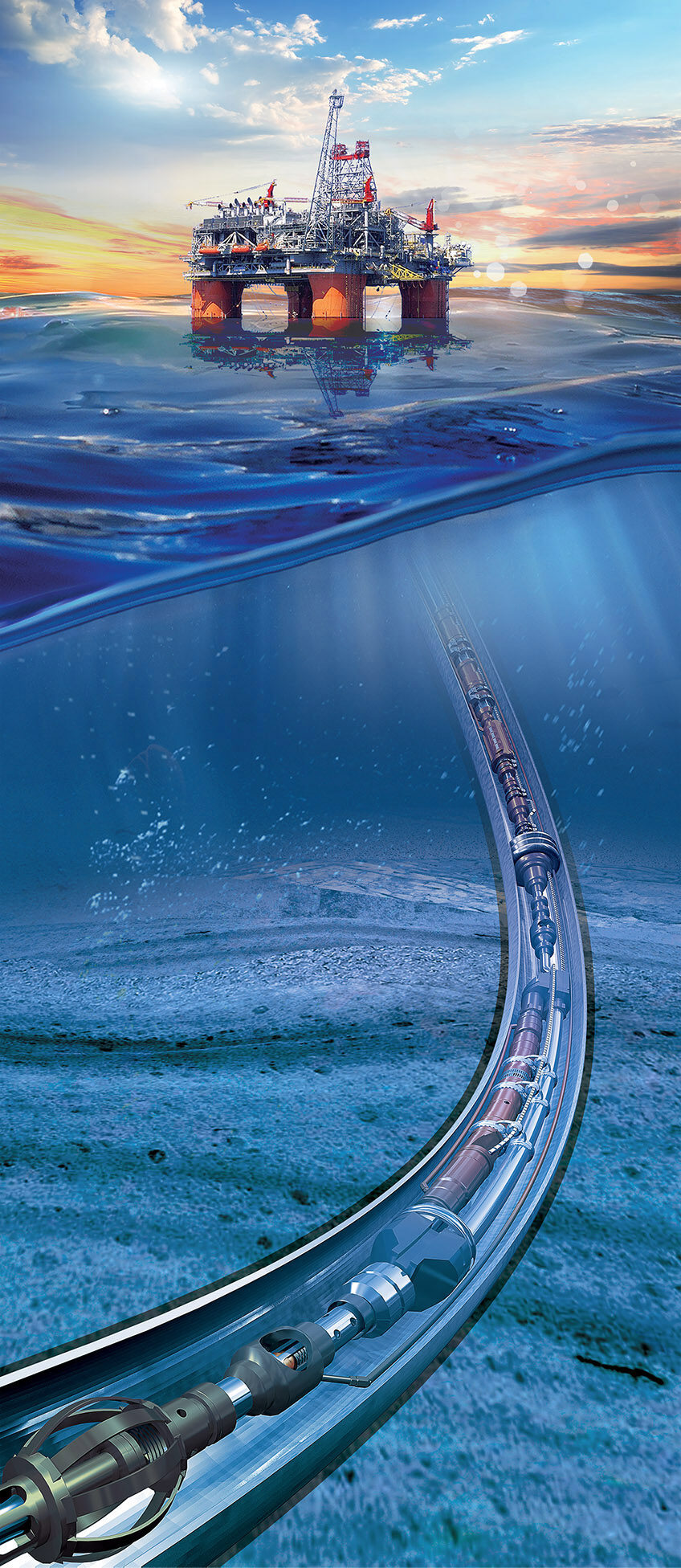

RBS provides several custom ball screw assembly configurations to simplify valve assembly, minimize valve bonnet size and improve ergonomics for ball screw operated (BSO) valves that are integral to Frac Tree assemblies, installed at the top of wellbores. These valves are crucial for isolating fluids within the well during frac operations and are designed to perform under extremely high pressure, making them ideal for multi-staged frac processes in the toughest environments.

Well Completions

RBS can provide several custom ball screw assembly configurations for electro-mechanical actuators used in well completions that must operate in harsh environments with wellbore fluids, high pressures and high temperatures for the life of the well.

Ball Screws

The use of ball screws allows for highly efficient ergonomic valve actuation for operators with smooth, reliable, and precise gate movements, ensuring optimal operation even in challenging environments and varying temperatures as well as use with remotely actuated gate valves with their reduced torque performance. Similarly, ball screws provide responsive and precise actuation control in well completions while helping reduce complex hydraulic control and potential for contamination.

Customization

RBS works closely with our clients from the early stages of product development to understand their unique design needs, creating custom ball screw assemblies that are fully optimized for the customer's specific application, and ensuring reliable performance in any environment. For highly corrosive environments, RBS can provide ball screw assemblies made from Incoloy, Inconel, MP35N and Stainless Steel to ensure corrosion resistance to wellbore fluids. In addition, for high temperatures RBS can use Stellite or cobalt alloy ball bearings in place of 52100 or 440C ball bearings.

Industry Leadership and Collaboration

As the preferred industry leader in linear motion, RBS is highly regarded for its expertise and innovation in creating custom solutions for the oil and gas industry. Our collaborative approach ensures that we work alongside our clients to develop tailored products that simplify the assembly process, eliminate unnecessary components, and enhance overall efficiency. RBS is committed to providing solutions that deliver both performance and reliability.

By choosing Rockford Ball Screw, you are partnering with an established leader in the industry, known for providing high-quality, engineered linear motion products that meet the rigorous demands of the oil and gas sector. If you're considering a design for your energy project, RBS is ready to support you with the industry’s best custom ball screw solutions.

Contact us today to learn how we can assist with your specific project needs.